Internal innovations in special machine construction

- Faster processes through support for internal innovations

- Advantages of 3D applications in special machine construction

Standing still is equivalent to going backwards. There is probably no other industry in which this is more applicable than in mechanical engineering. Technological progress is extremely rapid and as a German special machine constructor, we have been and still are consistently faced with the challenge of offsetting our international competitive disadvantages by offering special machines that are made in Germany at attractive conditions and in outstanding quality. Openness to internal innovations has always been the reason behind and objective of our success. Here you can find out more about how we support and implement internal innovations in special machine construction and why we are currently seeing plenty of potential in the area of 3D applications.

Key points at a glance

- Internal innovations are a crucial factor in business success.

- Technological advance can be used for faster and more efficient processes in special machine construction.

- The use of 3D applications is currently proving to be extremely promising in the area of mechanical engineering.

- With a combination of 3D virtual reality, 3D measurement and 3D printing (ideally with continuous carbon fibre), components can be designed, measured, tested and created in one consistent process.

- 3D applications can also be integrated into production processes to save time and money.

Interne Innovationen - Definition

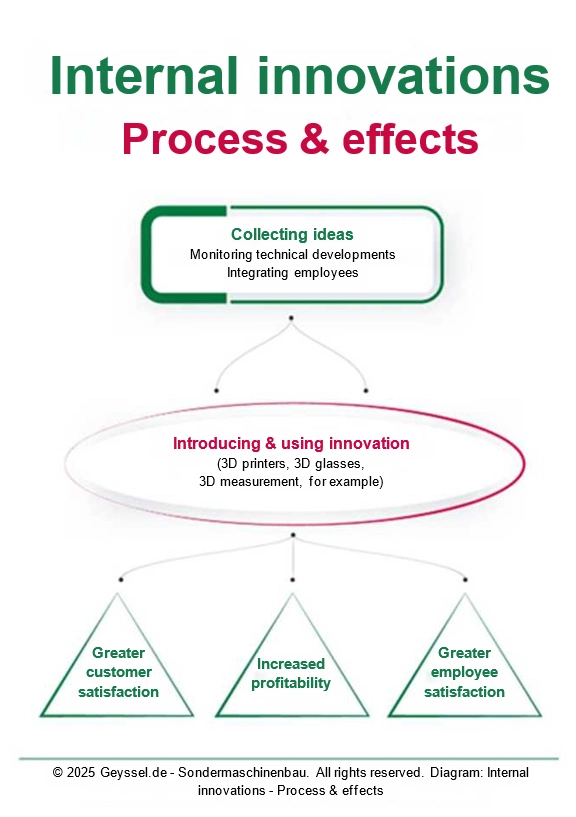

The term internal innovation refers to the development and implementation of new ideas, processes, services or products within a company. The source of innovations is usually either Research and Development or independent ideas. The objectives are improved profitability and greater customer and employee satisfaction.

Type of internal innovation

Innovations can encompass various areas and sometimes shape one another:

Product innovation

In the context of product innovations, new products, additional modules for existing products and better products as replacements for what was previously available are developed and tailored to specific customer requirements.

Process innovation

As a result of improvement and acceleration of processes, either through new technical options or better organisation, both customer service and profitability can be optimised.

Service innovation

New, additional and improved services can extend a company’s own portfolio and contribute to satisfying customer requirements through a comprehensive service. One example is training courses on commissioning of machines.

Technological innovation

New technical developments, such as 3D printers, 3D glasses, etc., can play a part in improving processes and products and developing new product innovations.

Importance of internal innovation in special machine construction

Technological progress is huge and, of course, presents challenges to companies in special machine construction. But we love a challenge! At Geyssel, we therefore exploit every feasible opportunity that presents itself to improve both customer satisfaction and profitability for our customers and ourselves.

We are currently working increasingly with 3D applications because they offer a variety of opportunities for optimisation.

Would you like to find out more about the innovative methods and processes that we are using to offer your the best machines possible? Then take a look here at our general project process for special machine construction and get in touch with us to discuss your requirements. We will be happy to put our machines and our expertise at your disposal.

3D applications - examples of internal innovations in special machine construction

3D techniques bring a wealth of advantages to special machine construction in particular, in terms of improvements in both processes and product quality.

3D glasses: Wider use of virtual reality for higher quality

Using virtual reality (VR) with 3D glasses opens up a wide range of new options for us in special machine construction. Here are just a few examples:

- With the help of modern 3D glasses, our developers can visualise their designs in a realistic way long before the machine or module is produced.

- In this way, our customers can also see the project in advance and compare it with their own ideas and requirements.

- Errors and unfavourable solutions (such as restricted servicing space, controls in ergonomically awkward positions and so on) can therefore be identified at an early stage and rectified well before production begins.

- Customer involvement in the project process and the machines themselves can thus be improved. Costly reworking is avoided, which can boost profitability enormously.

- In addition, 3D glasses can be integrated into production processes in industry to identify errors and problems more quickly.

3D measurement: Greater precision in mechanical engineering and production

Laser scanners and 3D coordinate measuring instruments are used in 3D measurement, for example, to check and measure products, machines and parts.

- Existing components and entire modules can be checked quickly and with high precision down to the last detail using 3D scanners.

- Inspection of incoming goods (parts, materials) can also be carried out in this way and defective parts are quickly identified.

- In the context of quality assurance, both in mechanical engineering and in production processes, deviations from specifications can be identified at an early stage using 3D measurement. This avoids tiresome problems with defective parts and the costs incurred for rework and reject parts.

- In addition, 3D measurement can be used for (retrospective) digitalisation of design data.

- 3D measurement can also be used for reverse engineering if components have to be copied but the digital design data is not available. The point clouds and mesh files generated during measurement can be imported seamlessly into CAD systems.

This technique is used, for example, when additional modules for which there is no 3D data have to be integrated into existing systems. Furthermore, systems can be adapted to existing conditions at production sites where space is limited using 3D measurement.

3D printing: Production of prototypes and components with continuous carbon fibre

3D printing with continuous carbon fibre represents a particular milestone for us in special machine construction, as we are able to produce not only samples and prototypes but also entire components with high strength/rigidity using “standard” 3D printers.

What is continuous carbon fibre?

Continuous carbon fibre consists of long, continuous carbon threads that are extremely strong and are therefore widely used in composite materials as reinforcement. It is often used in aeronautical engineering and the automotive industry, where light but robust materials are required. The material made in this way is just as strong as aluminium, but lighter.

- Special 3D printers can integrate continuous carbon fibre into parts and achieve very high strength, of a level that is certainly comparable with parts made of aluminium. We use this technology, for example, for components that were previously milled from carbon sheet.

- Using a special 3D printer with continuous carbon fibre, we can manufacture particularly heavy-duty components easily and quickly for special machine construction.

- Typical areas of application include, for example, grippers, adapters and sensor holders.

- Instead of simply producing samples and prototypes, as has been the case until now, real, usable, fully functional components can be produced by 3D printer, which reduces the process time.

- The settings of a 3D printer can be adjusted quickly and easily and the parts can therefore be produced in just a few hours.

- We can supply our customers more quickly and the costs of manufacture can be optimised in the long term.

Make the most of internal innovations through synergies!

Integration increases the added value of innovations. The combination of 3D measurement, virtual visualisation with 3D glasses and 3D printing therefore facilitates a digital development and production process. Fast and efficient, easy to control in-house.

Ideas can be visualised and validated quickly and turned into components, while samples and prototypes can be produced relatively quickly. This is a huge advantage in terms of cost and time.

Advantages of internal innovations

Companies that are open to new developments and specifically support and use internal innovations enjoy various competitive advantages.

Acquisition of new markets and customers

With new ideas, innovative products and fast & flexible production processes, companies can open up new markets, acquire new customers and simultaneously retain existing ones.

Increase in your company’s adaptability

Internal innovation processes help companies to become more flexible and adjust to changing framework conditions.

Cost savings through internal innovations

Where innovations contribute to simplifying and accelerating processes, there is a cost saving which benefits both the company and its customers. For example, it is significantly easier and quicker to make components directly with a 3D printer using continuous carbon fibre than to produce a sample, then perhaps a prototype too, before milling the part from carbon sheet. Of course, it is essential to consider the cost-benefit ratio and long-term technical development that is anticipated individually for each innovation.

Increase in customer satisfaction through more innovation

If a special machine can be supplied more quickly and checked more thoroughly, including virtual assessment in advance, the advantage to the customer is clear. This applies not only to the example of special machine construction, but also to any situation in which products or processes of higher quality are made possible by innovation.

Increase in employee satisfaction by supporting innovation

Ideas and suggestions for improvements from employees should always be regarded as valuable. On the one hand, staff often work directly with customers and experience the problems, challenges and dissatisfaction with products and services they have at first hand. On the other, employee satisfaction and loyalty increases as soon as staff feel appreciated. Especially at a time of increasing shortages of skilled employees, this is hugely important.

Challenges connected with internal innovations

Although internal innovations bring plenty of advantages, the challenges associated with them should also be taken into consideration:

Innovation requires resources

Innovations cannot be integrated into day-to-day work casually. Sufficient personnel, time and money are required to handle innovation processes effectively. But even if this requires upfront investment: it pays off in the long term! The new procedures will save costs in the medium to long term. In addition: a company that is not moving forward cannot survive on the market over an extended period.

Innovations entail changes

Employees (and some customers) often do not have a particularly positive attitude to anything new. Established practice is trusted and has always worked fine in the past. Take these concerns and reservations seriously as a company, while still creating a climate that welcomes new ideas and innovations and take suggestions for improvements on board. Show that new ideas can lead to many improvements and your employees will embrace them in the long term.

Measuring and evaluating success

Try to measure the success of innovation projects and make them known. Draw up comparisons and look at the costs of the project on the one hand and the potential long-term savings on the other.

What are the sources of internal innovations?

What is the best way to initiate internal innovation? Ideally, by starting wherever you find the sources for new ideas and new technologies:

Employees as a source of internal innovations

Ome of the most important sources of new ideas and suggestions for improvements are your own employees. They often work directly with customers, participate in installing machines on the customer’s premises or train their staff. They see at first hand where action is needed. Ideally, employees should act as “intrapreneurs”: as internal entrepreneurs driving forward with their own innovation projects.

At Geyssel Sondermaschinenbau, we have a tradition of attaching a great deal of importance to feedback from our employees, irrespective of any hierarchies. The team members who install and commission our machines on site and run the training for our customers are the first to find out where there is potential for improvement, where there are still uncertainties for our customers and where solutions should be found. We take this feedback extremely seriously and try to take account of it in future projects. This has always enabled us to respond to customer needs in an agile way.

Research and Development as a source of innovation

Invest in your own Research and Development department and/or collaborate with universities or research institutes and/or support doctorates. In these ways, you can ensure that you always have access to new technological developments.

External networks as an important source of information

Use workshops, advanced training courses and industry meetings to talk to experts. Keep up to date with the latest developments and share your experiences with colleagues. You will get many useful tips in this way.

Openness of the management to innovation

Last but not least, it goes without saying that the management of a company must be open to new ideas and innovations. Keeping employee suggestions on file and reading about new technology but not actually using those resources in your own company is not the right approach. Always ensure that the management of your company supports innovation processes and ultimately implements them in a strategic way.

Conclusion

As a medium-sized company in the field of special machine construction, we have been and still are able to guarantee our success solely through continuous adaptation to technological development. We therefore not only work closely with technical universities, but remain open to new opportunities such as 3D applications at all times. In addition, we have long been acting on the feedback from our employees who install our machines on customers’ premises and provide training for their teams. Would you also like to benefit from our strength in innovation? Then get in touch with us and find out more about how we can help you with your specific challenges.

FAQs

What are the advantages offered by 3D printing with continuous carbon fibre?

When 3D printers integrate continuous carbon fibre into parts, they are almost as strong as aluminium but are lighter in weight. The components are also available to use quickly, while samples and prototypes are no longer essential.

How can innovations improve profitability in special machine construction?

If the process of designing, evaluating and constructing special machines is accelerated and improved in terms of quality through innovation, time and money are saved and profitability improves. Opportunities of this sort are provided, for example, by the use of 3D glasses for assessment and quality assurance and the production of components by 3D printer with continuous carbon fibre.

Why are innovations important in special machine construction?

Technological progress is rapid and mechanical engineering companies that do not keep pace can easily find themselves at a disadvantage among international competitors. Using new ideas and technological opportunities such as 3D applications can therefore be crucial for the success and survival of a company.